Hybrid and electric vehicle (EV) motors require compactness, high power output, and low power loss, but engineers have had a difficult time in achieving such performance because data used for design was incomplete.

In the past, magnetic property of non-oriented magnetic steel sheets used for motors and other parts were measured with the Epstein method, single plate magnetic test method or some other method and the measurement data were used for design.

It is known that the data measured with these methods are generally averaged in the rolling and perpendicular directions, so do not precisely represent the material properties.

One reason is that even "non-oriented" steel sheets have a magnetic anisotropy and their magnetic properties vary according to direction.

In addition, Prof. Enokizono of the Faculty of Engineering, Oita University and his co-researchers have been discovering that the directions of magnetic field applied and magnetic flux generated inside the material, which were believed to be the same, are actually different.

The property that can be measured with this analyzer are called "two-dimensional magnetic property".

Development of a high-energy-density motor which makes the most of material properties requires precise measurement of the two-dimensional magnetic property, as well as quantification, in terms of vector relations, of the magnetic flux density, magnetic field strength, and skewing between the two (phase difference), and accurate analysis of the magnetic field.

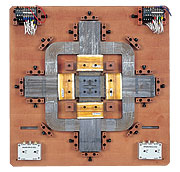

The IE-1131B V-H Analyzer, which is equipped with a newly developed two-dimensional drive yoke and highly accurate magnetic field vector sensor, measures the vector relationship between the magnetic flux density and magnetic field strength in all the directions of steel sheet at a high speed and accuracy.

This dramatically increases the analysis accuracy for the magnetic fields of the motor, transformer and other parts and drastically reduces time needed for the device design and simulation.

Measuring method: X and Y detection coil method

Measuring frequency: DC to 1 kHz

Maximum magnetic flux density: 1.5 T

Magnetic field detection section: Orthogonal slim H-COIL

Induction voltage detection section: Orthogonal detecting coils set to the specimen